Mid-drive motor vs. hub motor

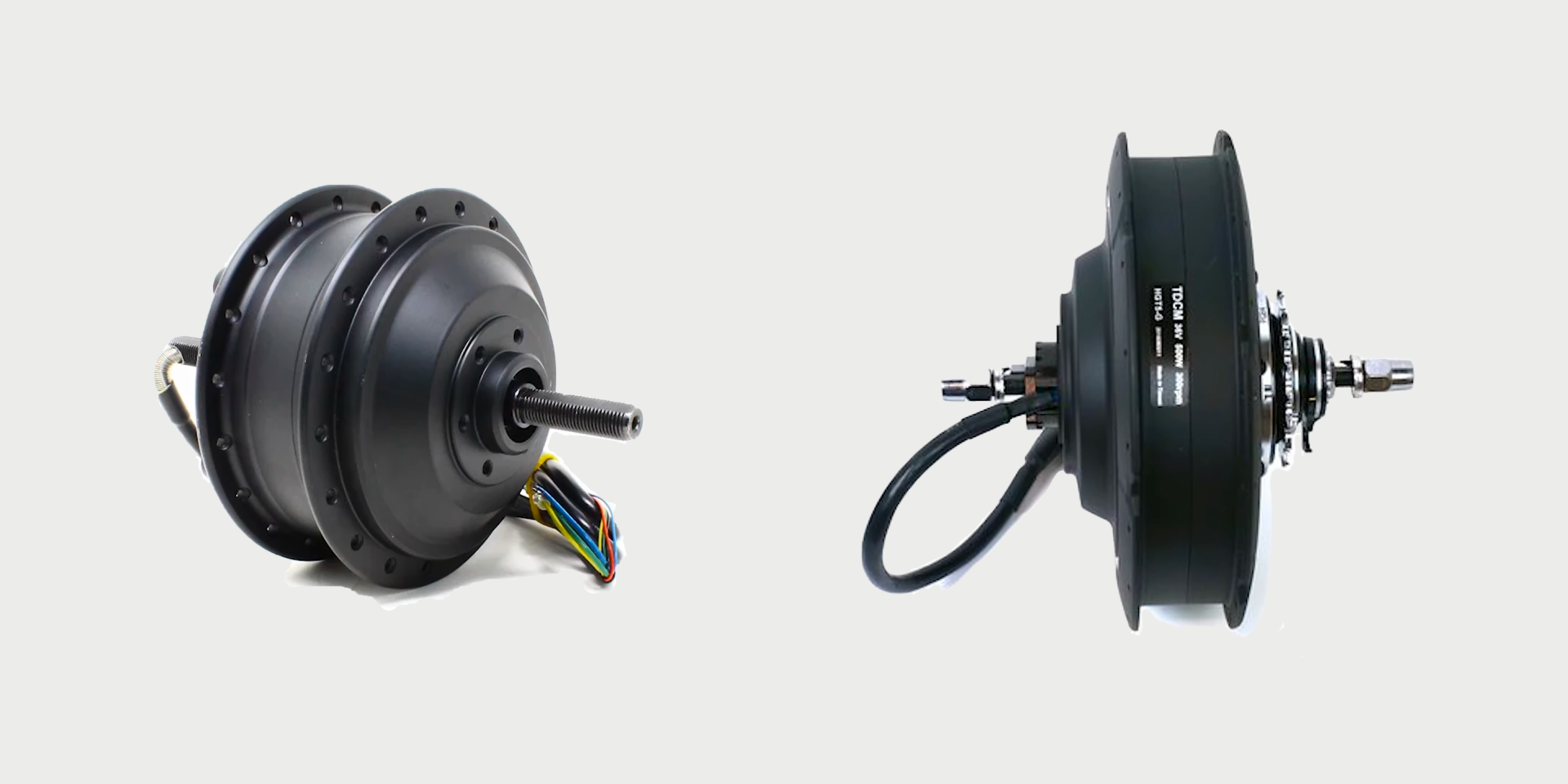

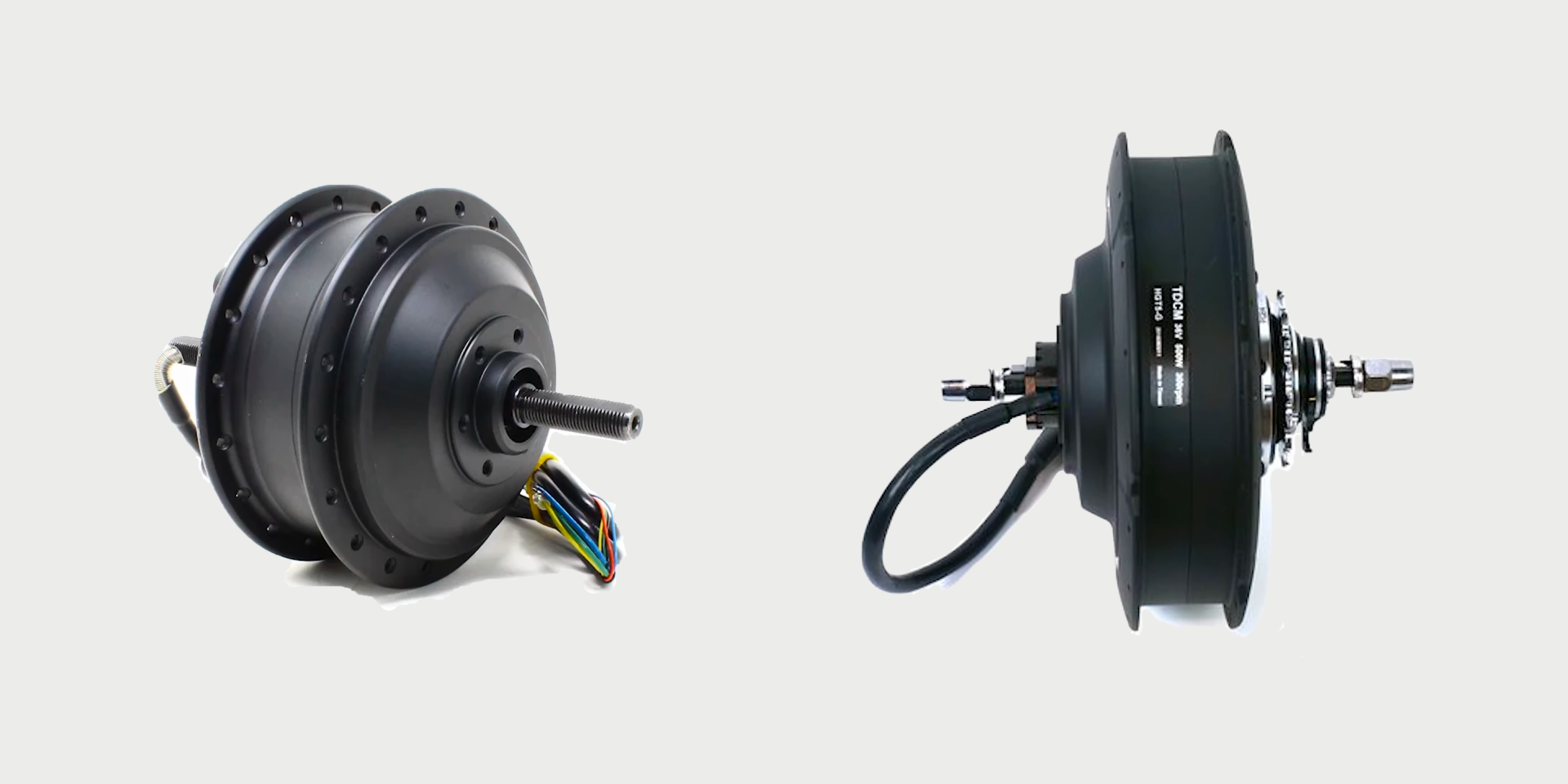

Hub E-Motor: Geared motor & Gearless (Direct-drive) motor

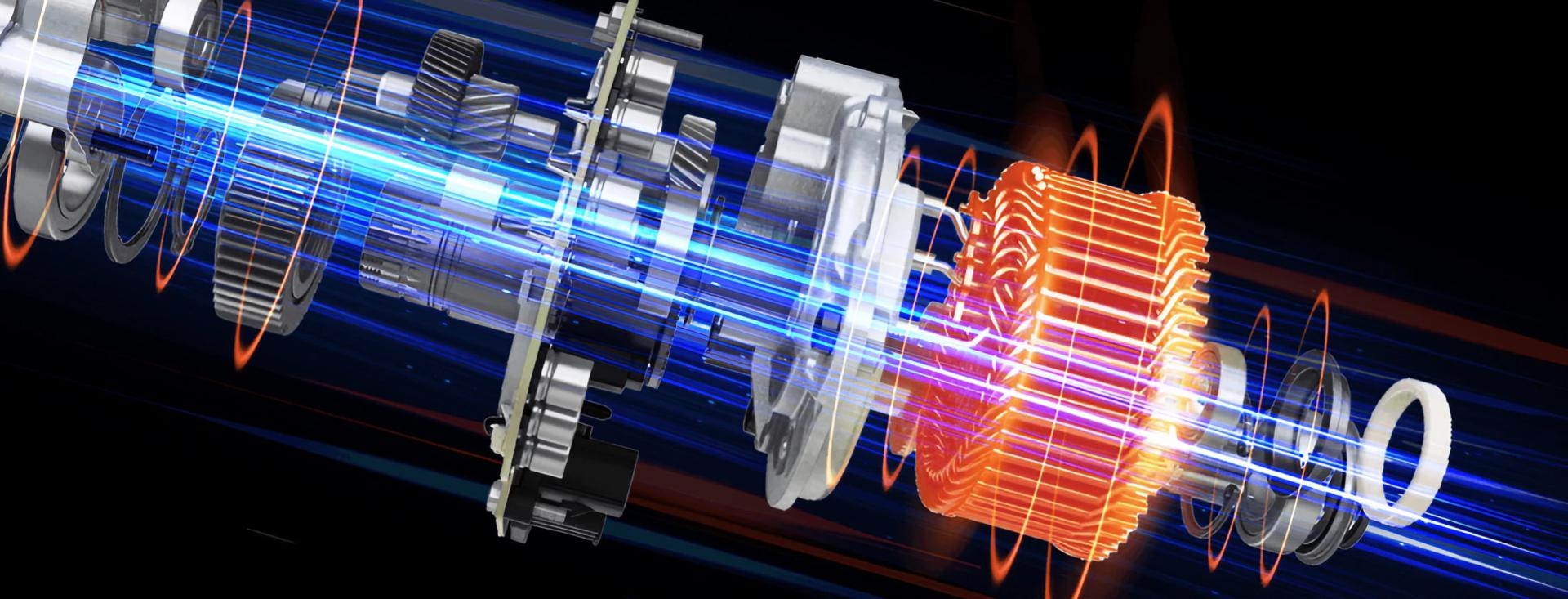

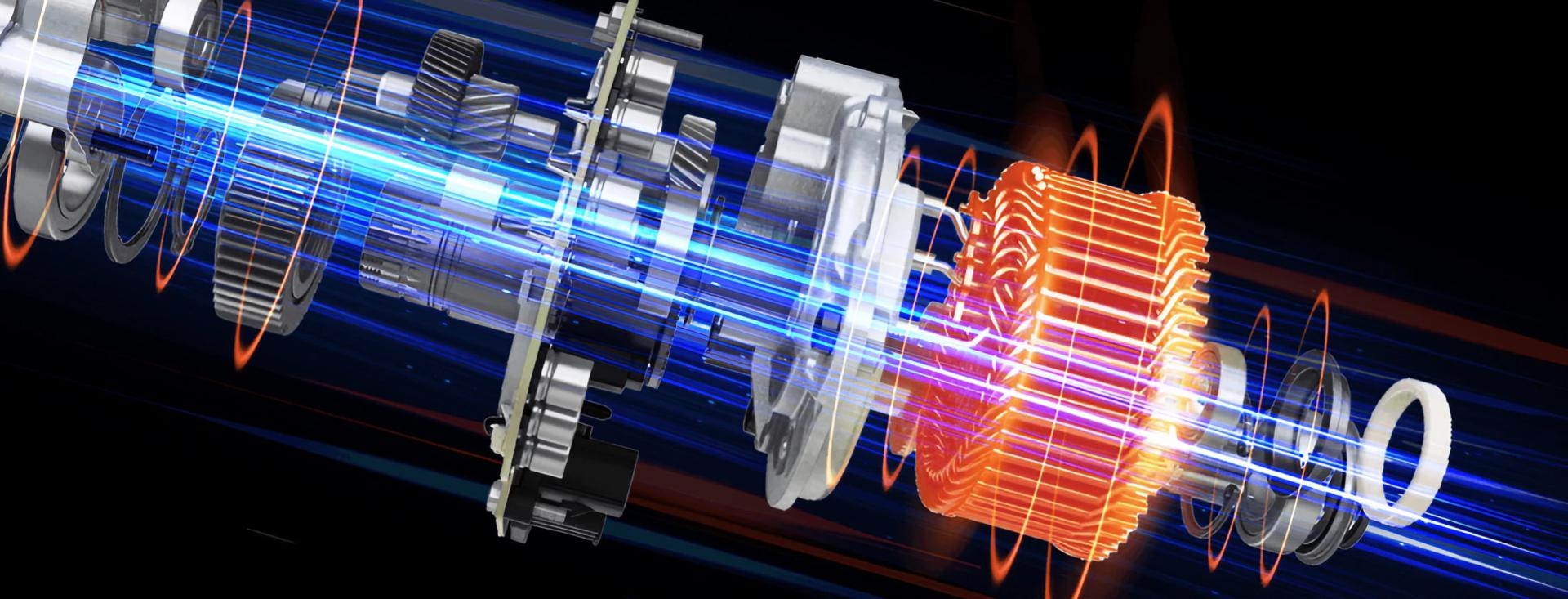

Mid-drive motor

Why a mid-drive motor is the right choice for eBikes

-

Efficiently, using bike gears allows for the motor to optimize its power consumption

-

Motor location keeps the bike feeling balanced between the wheels

-

Higher torque outputs, ideal for steep terrain and heavy loads

-

Manages heat better for more strenuous sustained use

-

Torque sensor makes a more natural pedaling feel when engaging the motor

-

Rear wheel maintenance is unaffected by the motor

Why Macvol surge e-motor is better than others

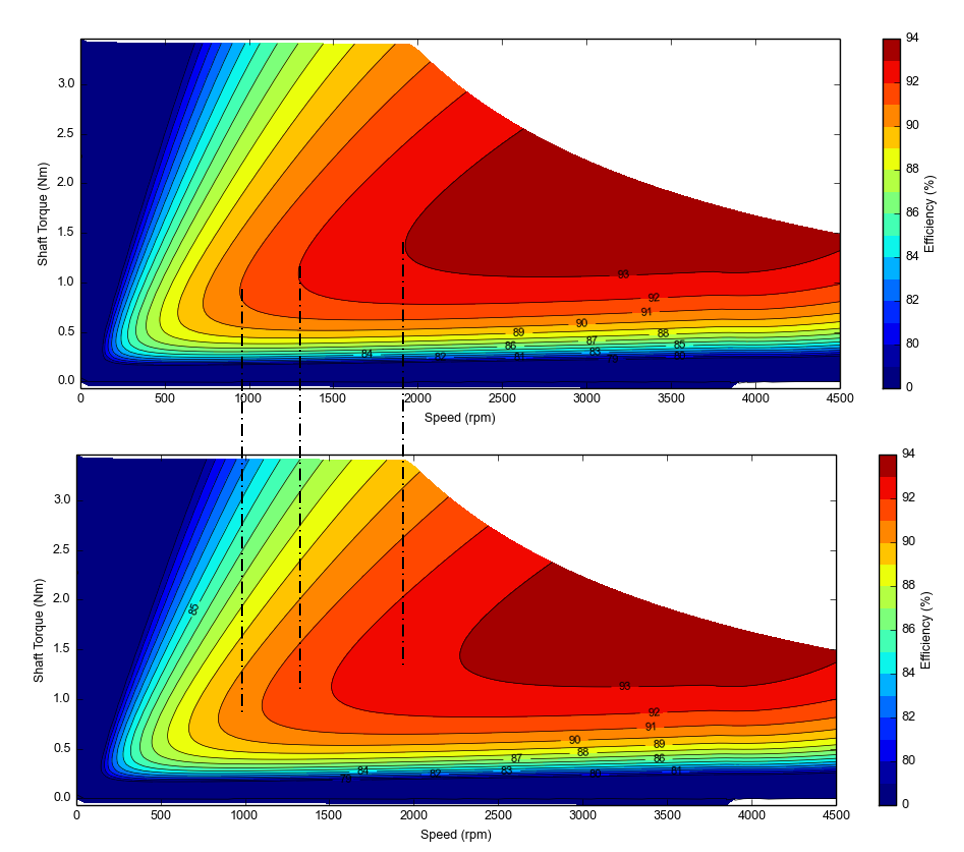

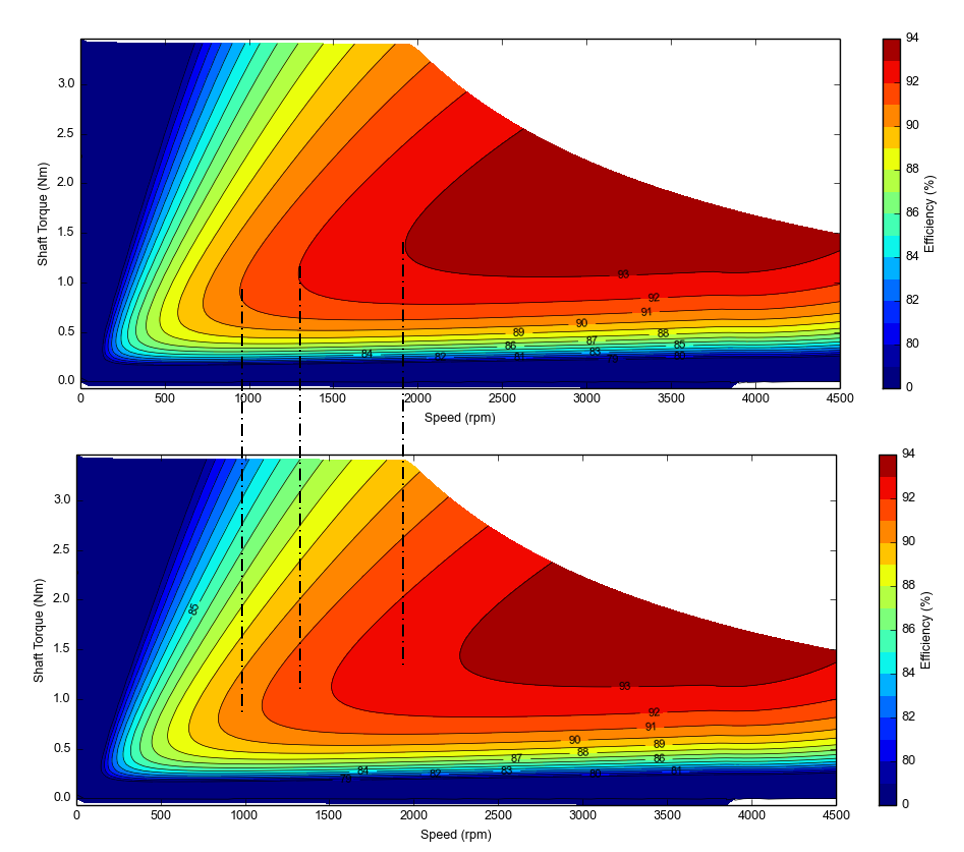

High Efficiency

Flat Wire Winding

- For the same power, smaller size, less material, lower cost or for the same size, higher slot filling rate, higher power density.

- Larger winding cross-sectional area, less dense, lower resistance, higher efficiency at heavy load point.

- Better temperature performance, less internal clearance, better contact between flat wires and flat wires, between windings and core slots, larger contact area, better thermal conductivity.

- Flat wire windings are more rigid, and with the optimization of the rotor pole structure can have better NVH performance; the result is a 10% increase in true copper slot fullness, and the 10% increase can be converted into a variety of directions (volume, weight, and energy efficiency) Tandem chose to use this 10% for energy efficiency improvement.

True copper slot fullness increased by 10%

In comparison, Bosch motors are not able to guarantee a continuous output of 250W at a temperature of less than 60 degrees Celsius in the motor casing, so in accordance with European Union standards, a high temperature label is required on the outside of the motor. MACVOLTRACK's high power output and efficient heat dissipation design enable Surge e-Motor to keep the temperature within the EU standard.

Integral Potting of Motors

The motor potting process usually refers to the use of potting adhesive (also known as encapsulating adhesive) to seal and secure the inside of the motor to prevent moisture, dust or other impurities from entering the motor, thereby significantly improving the performance and life of the motor. The advantages are as follows:

-

Dust and moisture resistance: Potting compound can effectively seal the inside of the motor to prevent dust, moisture and other impurities from entering, thus protecting the internal parts of the motor from damage and corrosion.

-

Improve insulation performance: Potting compound can improve the insulation performance of the motor and prevent short circuit between electrical components, thus improving the safety and reliability of the motor.

-

Reduce vibration and noise: Potting compound can fix the internal parts of the motor, reduce vibration and noise, and improve the smoothness and comfort of the motor.

-

Improve durability: Through the potting adhesive process, the internal parts of the motor can be better fixed and protected, thus prolonging the service life of the motor.

Mute Optimization

- Material optimization: the gears are made of a single piece of peak material, the material grade is kept confidential and the noise generated by the friction between the gears is reduced while ensuring the same stiffness as the metal material.

- Process optimization: after the assembly of all components in the motor is completed, all components are fixed with potting adhesive, and the cavity is filled with adhesive to ensure that there is no noise generated by vibration between the components, to improve the overall stiffness, to reduce electromagnetic noise, and to fan the heat quickly.

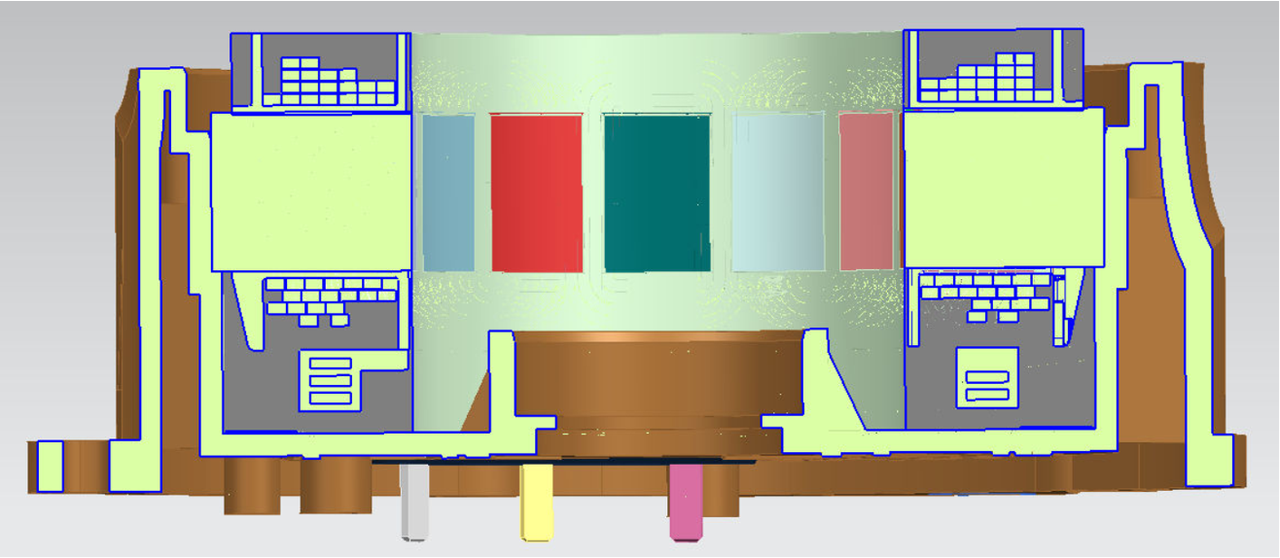

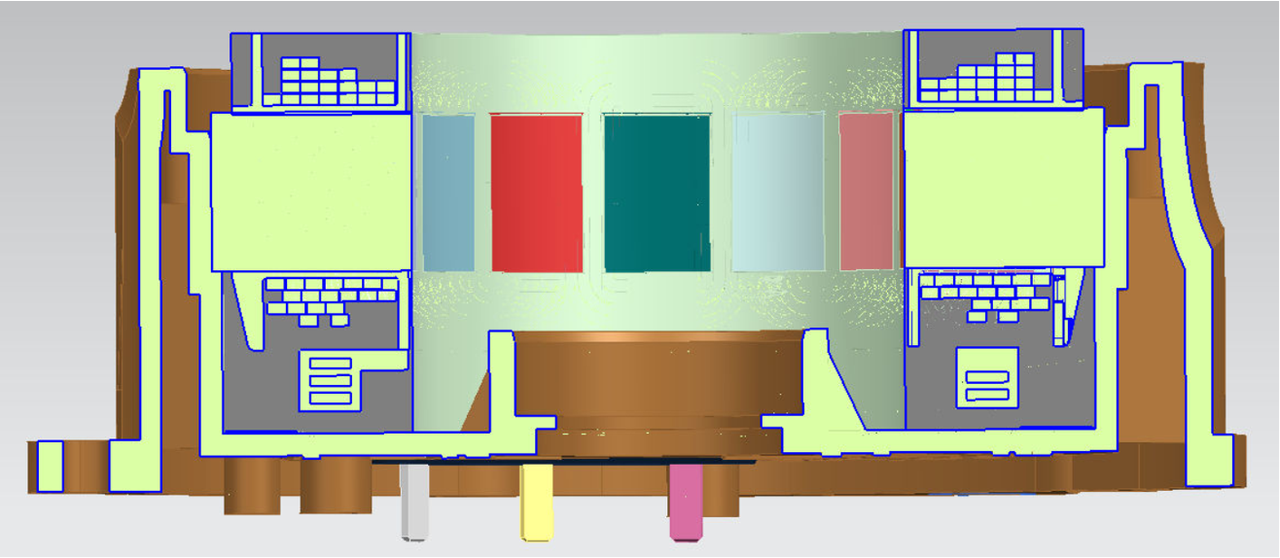

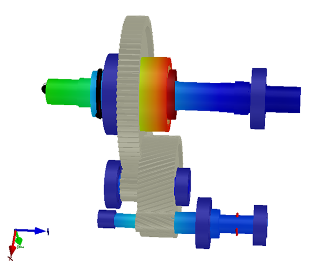

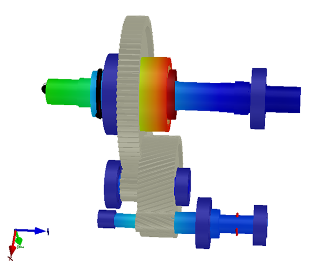

- Dynamics simulation optimization: improve the support stiffness of the system, optimize the transmission error of the system, the sound pressure level at the human ear decreased by 7.3dBA

Noise testing at the human ear position.

Dynamics simulation.

Cycling Experience

Pedaling air travel in a cycling motor is the minimum distance or angle that the pedals must move down before pedaling begins. This air travel is usually detected by a sensor in the motor controller to trigger the generator to start and provide power support.

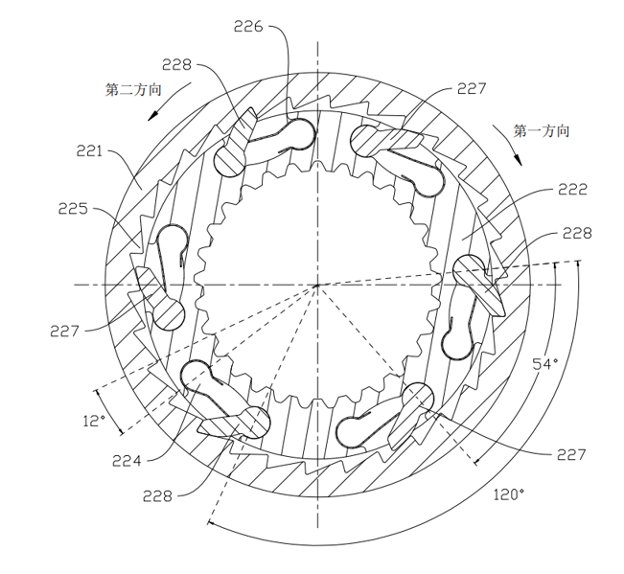

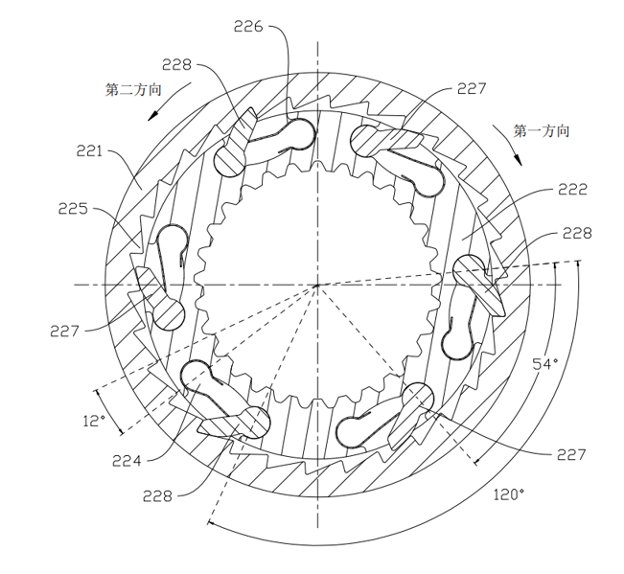

The Surge series motors have a ratchet clutch with a small amount of air travel (6° or less), which makes for a good pedaling experience (PS: the larger the air travel angle, the more pronounced the feeling of stepping out of the way when pedaling), while the market competes with air travels ranging from 6.92° to 7.2°.

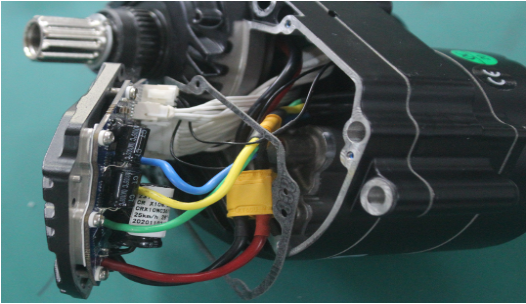

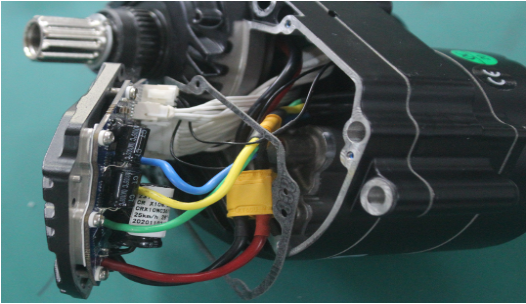

Manufacturing, Assembly Processes

-

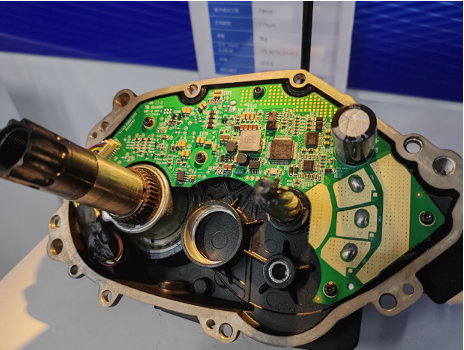

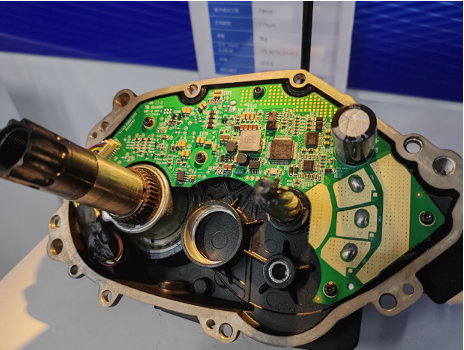

The circuit control unit of the motor, including the main control MCU, drive and power MOS, torque sensor are all automotive-grade chips, which are superior to competitors in terms of temperature rating, reliability, functional safety and life rating.

-

The one-piece electronic control connection greatly improves the stability and reliability of the system, avoiding frequent shaking and high and low temperature impacts that cause the wiring harness to fall off and aging.

-

Surge series motors are fully automated in Vietnam to ensure the stability of quality and consistency of performance. Most of the competitors do not have automated production lines.

One-piece connector

Flying lead wiring

Deutsch

Deutsch  Español

Español  Deutsch

Deutsch

Validate your login